Loading...

Loading...

Loading...

Loading...

The specialized initiation board "Cricket" is designed for remote mining using UAVs. By combining a magnetometer, accelerometer, and self-destruction functionality, the device ensures precision, reliability, and safety in creating mine-explosive barriers.

Intelligent Detection: Responds to distortions in the magnetic field.

Versatility: Its compact design allows integration with various standard and custom explosive devices.

Autonomy: Operates on a built-in power source with a predefined operational period, after which it self-destructs automatically.

The specialized initiation board "Cricket" is designed for remote mining using UAVs. By combining a magnetometer, accelerometer, and self-destruction functionality, the device ensures precision, reliability, and safety in creating mine-explosive barriers.

Intelligent Detection: Responds to distortions in the magnetic field.

Versatility: Its compact design allows integration with various standard and custom explosive devices.

Autonomy: Operates on a built-in power source with a predefined operational period, after which it self-destructs automatically.

Enables mining in hard-to-reach or enemy-controlled areas without involving personnel. The device is deployed via UAV and activates after a preset time, minimizing risks to military personnel.

"Cricket" is installed beneath the main mine, ensuring the detonation of both charges if an attempt is made to remove it. Effective against sapper operations in combat conditions, making demining impossible.

Allows ambushes using only explosive devices, eliminating enemy personnel and equipment without operator involvement. Use Cases - Route Mining, Neutralizing Small Units,Operation Disruption

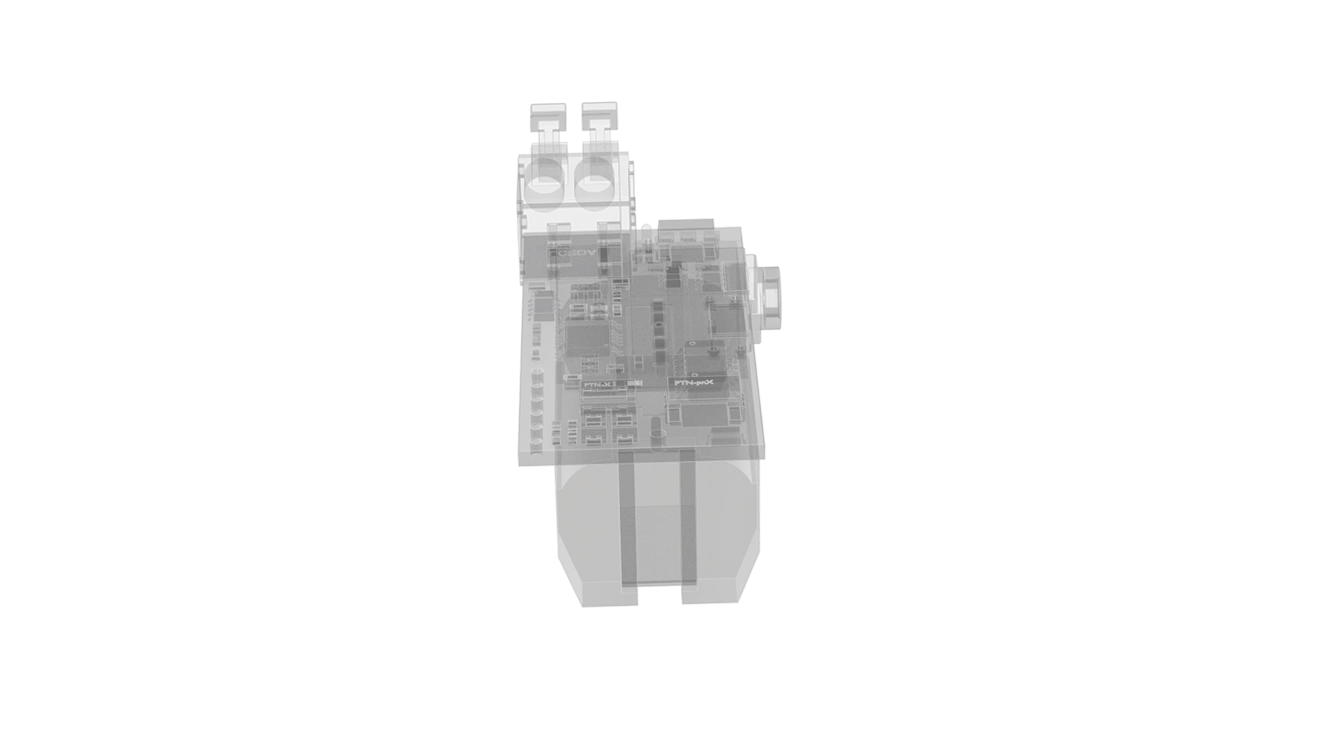

01"Cricket" АМ1

A modification equipped with an accelerometer and a magnetic sensor on a single board.

This combination makes the device an effective solution when used against enemy wheeled and tracked vehicles.

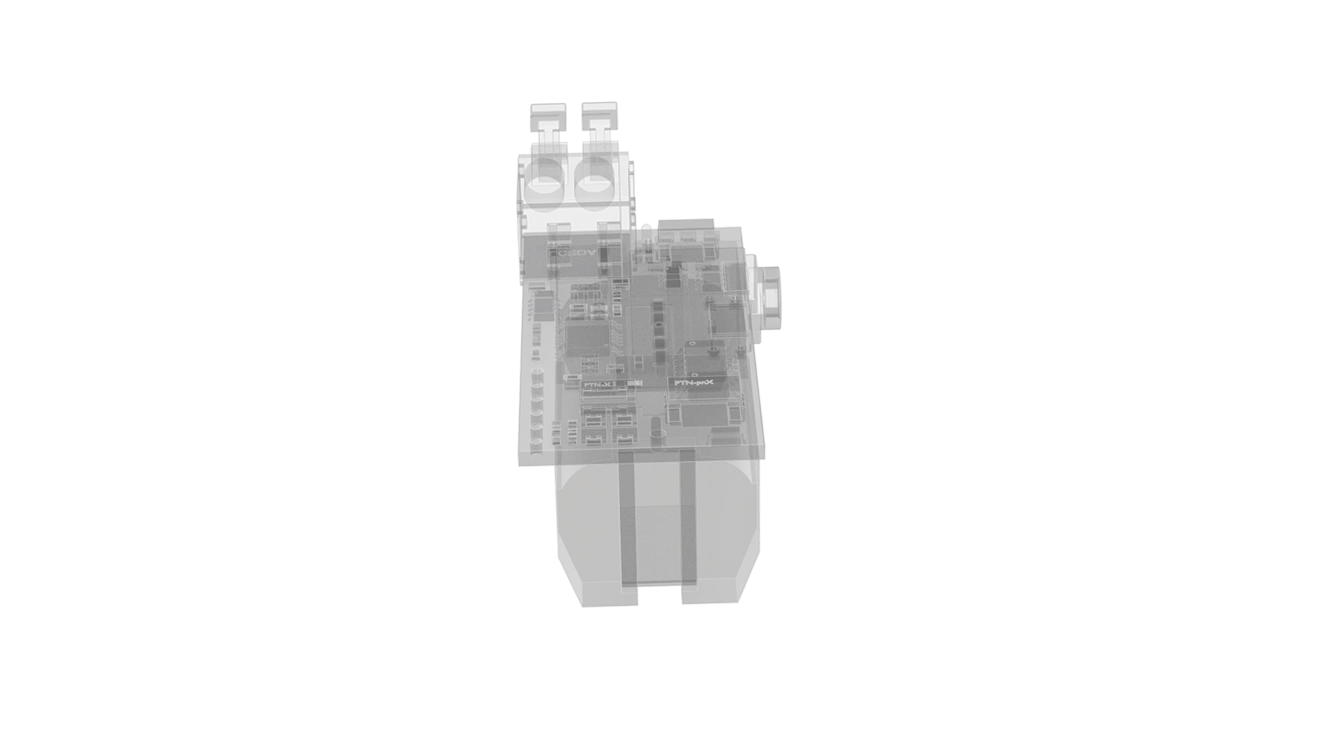

02"Cricket" АM2

A modigication with special designed box for easy installation into PTM-3 mine

- We perform incoming inspection of components using modern microscopes.

- An additional visual check is done before final assembly.

We test critical components for compliance with requirements using precise measuring instruments.

We analyze the energy consumption of the finished product, comparing it with a reference sample.

We use unique markings to ensure feedback and track quality.